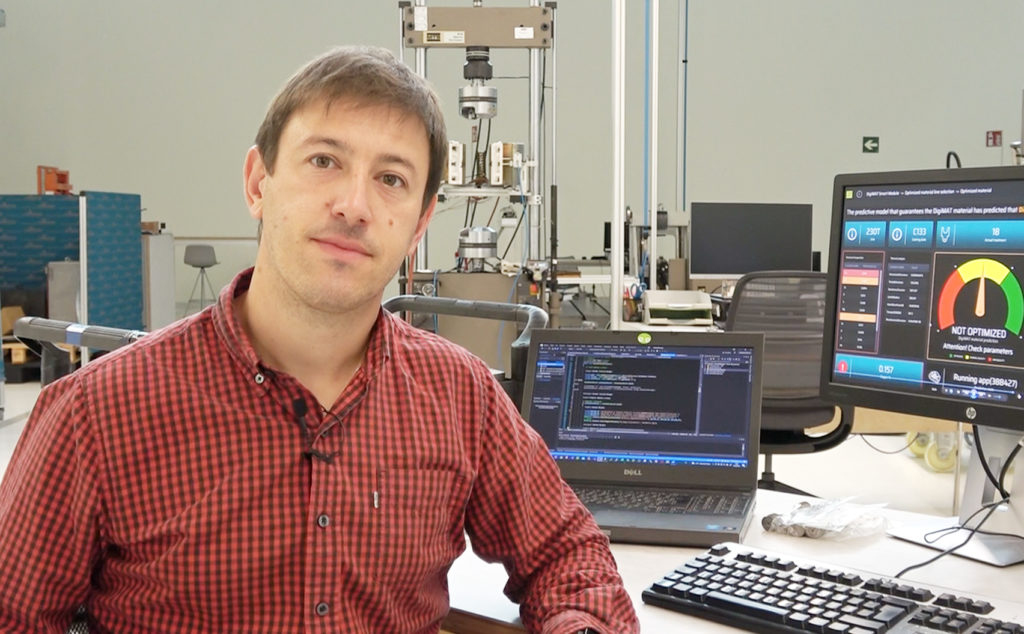

Asier González

VEIGALAN Project Manager

VEIGALAN is a software developing company focused in the creation of advanced solutions for the control and optimization of metallurgical processes.

Within DigiMAT project, the VEIGALAN team has been in charge of developing the digital architecture and the logic behind the DigiMAT Smart Module, making it possible to create new grades of casting materials with improved mechanical propperties. Nevertheless the success of DigiMAT project goes beyond the specific targets of the project being replicable for other materials and industry sectors.

Asier González, project manager and developer of VEIGALAN explains the main outcomes and achievements of the project for the metallurgical software company.

What was the main aim of the VEIGALAN team when DigiMAT project was launched? Have you achieved your goals?

The main task carried out by our team has been to provide, through technology, a predictive system that informs the operator in real time whether the parts being produced will meet the requirements defined for the DigiMAT material.

After showing propper performance and validation results of the system, we can assure that we have created a highly reliable solution.

Could you explain what a digital material is?

We call digital material to the foundry material that has been developed from digital technology. This technology allows obtaining very valuable conclusions making it possible to both improve the process and use it in real time to predict what will happen in the future (the end of the manufacturing process). Among the technologies applied, the most prominent ones are Data Mining or Artificial Intelligence models.

Which are the main challenges the workteam has had to overcome during the DigiMAT project?

One of the biggest challenges in this project has been getting a good data set in time to run the experiments. The impact of the pandemic on the automotive sector has significantly decreased the production of parts, substantially delaying data collection.

Could you highlight the main outcomes of the project when it comes to your field of knowledge?

From the point of view of a technological partner like us, Veigalan, we highlight the work perfomed in the field of data analysis, as well as the incorporation of technologies used in other areas, such as video games, to be used in the metallurgy sector.

Do you think DigiMAT results are replicable with other materials, components, or industry sectors?

In DigiMAT we have shown that, if we have a good set of data, we can both obtain the key to develop a new material and predict any existing other material with a high degree of success. Therefore, the answer is yes, this experience is 100% replicable.

What is next for Veigalan in this field?

Once the capacity of the classification algorithms for the creation of new materials has been demonstrated, the next step for us is to verify the capacity of the optimization algorithms to manufacture a material with the lowest cost possible regarding raw materials while meeting specifications from clients.